Two MIT undergraduate students recently won first place and $2,000 in the annual ASM Materials Education Foundation 2023 Undergraduate Design Competition. Louise Anderfaas and Darsh Grewal, students in Professor Gregory Olson’s class 3.041 (Computational Materials Design), collaborated with MIT postdoctoral advisor Margianna Tzini on this complex project.

“This is probably the highest level of complexity that an undergraduate team has ever taken on,” said Olson, who came to MIT in 2020 from Northwestern University and has coached teams at both schools. Last year, MIT took third place for designing a 3D printing alloy for stamping Tesla parts.

The ASM Materials Education Foundation is the philanthropic arm of ASM International, a materials engineering organization. It promotes applied science careers among students and faculty.

Super strong and affordable

Anderfaas and Grewal’s winning project was to create a 10-centimetre-thick ultra-strong aluminum plate for use in applications such as aircraft and automobiles. Crucially, the material must be extremely tough and resistant to phenomena such as stress corrosion and fracture. They created a video explaining their step-by-step process, using computer models and calculations to find the best combination of materials and design.

“In order to make the material affordable and usable for industrial applications, we used traditional machining methods,” Anderfas said, referring to traditional manufacturing methods such as cutting and milling, rather than more cutting-edge technologies that offer greater High performance and other benefits but tend to be more expensive. “But in order to use it on airplanes, we have to build it at scale.”

Anderfaas and partner Grewal, both seniors in the Department of Materials Science and Engineering (DMSE), had just three months to integrate all these features and use computational tools to speed up their designs.

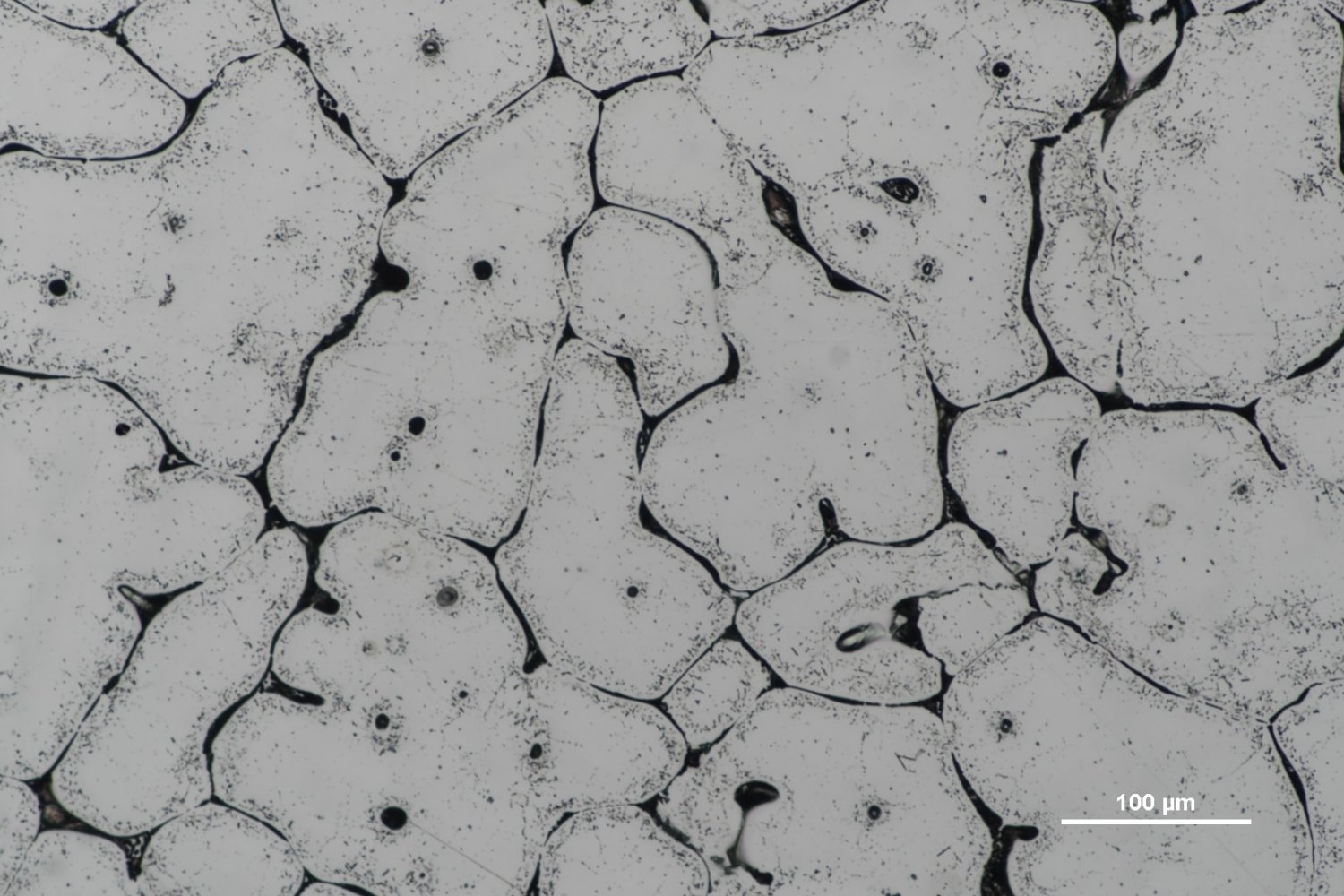

This ultra-high-strength aluminum alloy plate meets the practical performance requirements provided by Singapore’s DSO National Laboratory in partnership with MIT for this project. To develop a material that is strong, flexible and able to withstand pressure without corroding, the students used computational tools based on CALPHAD, a method of calculating material properties, combined with density functional theory (DFT) data. DFT data provides insight into a material’s electronic structure, helping to optimize its performance.

The team used multi-objective optimization, which was key to balancing the necessary variables. “When you try to design something in-house, there’s always a cost. When you try to add strength, you lose something else,” Grewal recalled. For example, making something more powerful might make it less flexible. Therefore, “rather than focusing on individual attributes, we look at the system as a whole.”

Anderfas and Grewal cited the classic layered approach to material design that Olson teaches in class. “It works two ways, structure affects attributes and attributes affect your structure,” Grewal said. “You have to understand the relationship.”

Challenge: There are many relationships to distinguish in a complex problem. “You have to distinguish which parts are important and how all those parts relate and connect to each other,” Grewal added.

Anatomy of Computational Design

Olson’s course breaks new ground in the field he helped invent: the computational design of new materials. The course brings together core concepts from MIT’s materials science curriculum—such as thermodynamics, kinetics, and mechanical properties—and teaches students how to design materials by understanding the process-structure-property-performance relationships that define material behavior. The course concludes with a final design project (the theme of the competition) in which student teams design a novel material to solve a current, real-world materials challenge.

“I have dedicated my research career to this technology and its commercialization,” said Olson, professor of the practice of DMSE at Thermo-Calc. Through his startup QuesTek, the technology has been adopted by industry giants such as Apple, SpaceX and Tesla. “These companies tend to be very interested in students who take my courses and often offer internships and some permanent positions.”

The course is organized into team projects from funded graduate research, so graduate students and postdocs can serve as coaches for student teams, allowing them to reach a higher technical level than they would otherwise, Olson said. Tzini walked the students through the specifics of the project, helping them distinguish different aspects and then connect them.

The database the students used for the project is aligned with the Materials Genome Initiative, a U.S. government initiative designed to accelerate the discovery and development of new materials. They include information about the properties, structure and behavior of various materials. Just as the human genome serves as a database to guide the assembly of living structures, here the materials genome contains the same fundamental data that can be used to guide the assembly of multi-scale microstructures of materials that evolve throughout successive stages of processing.

“So the database allows us to take the mechanistic knowledge that we have and apply it in a way that is specific to quantitative systems. The course really brings the entire curriculum of the undergraduate materials program into these design projects,” Olson said. He’s proud to see students like Anderfaas and Grewal succeed in the subject.

The students were surprised but delighted with their victory in the ASM competition. “It’s difficult to grasp all these concepts and balance everything,” Grewal said. “This was definitely the hardest class I’ve ever taken, but also the most rewarding.”

Second place in the competition was awarded to Purdue University for improving the flattening process for forged aluminum parts; third place was awarded to Michigan Technological University for reducing the presence of boron impurities when making cast iron from recycled steel.