Whether you’re a new employee, a gymnast, or a bendy straw maker, there’s one trait that’s ideal across the board: flexibility.

The same is true now for prototyping electronic devices. While designers often test their designs on “breadboards,” or thin plastic sheets that can hold electronic components together, they are often stiff and slow. Given the rigidity of these electronic backbones, MIT researchers have developed the “FlexBoard,” a flexible breadboard that can quickly create interactive interfaces on curved and deformable surfaces, such as balls or clothing. Prototype sensors, actuators and displays.

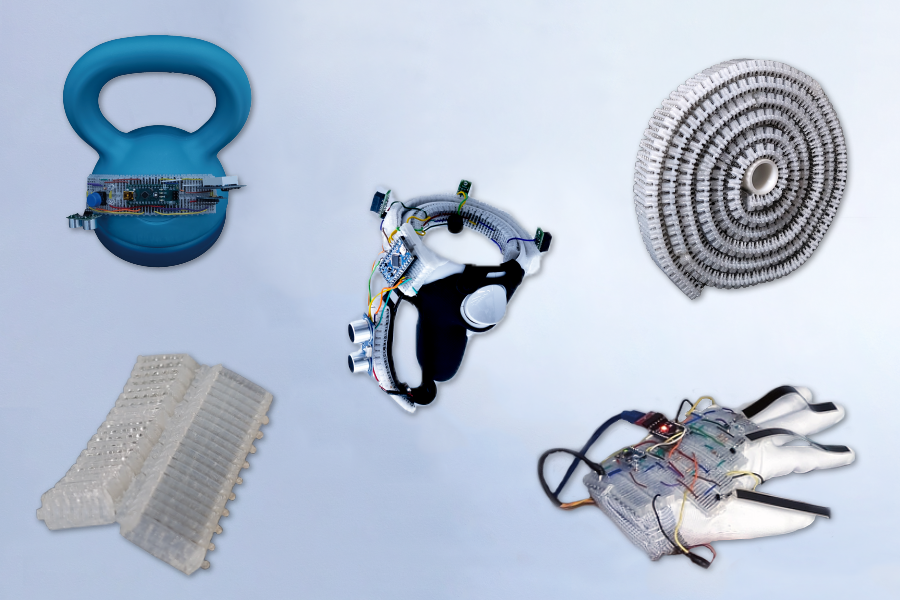

To illustrate the platform’s versatility on different items, the researchers tested it on kettlebells, video game controllers, and gloves and found that sensors and displays could be attached to electronics within each hinge. The team added sensors and LEDs to the kettlebells to successfully detect whether users were using correct form during swing training. In turn, the display will show red if performed incorrectly and green if performed correctly, along with the number of repetitions. In the future, the platform could improve fitness habits by providing feedback.

Breadboard designs consist of thin plastic joining two pieces of the same material for enhanced flexibility. This “living hinge pattern” can be found in the spines of condiment bottle caps and plastic tray cases, where they hold the FlexBoard’s electronic components together. The design can be replicated with off-the-shelf 3D printers, creating a FlexBoard that can be sewn onto items or secured using epoxy glue or Velcro tape.

This convenient design opens the door to more quickly customize the interface. “A fundamental development in the modern world is that we can interact with digital content anytime, anywhere, through ubiquitous Interactive devices.” Now an assistant professor at Aarhus University. “FlexBoard supports the design of these devices as a versatile and rapid interactive prototyping platform. Our platform also enables designers to quickly test different configurations of sensors, displays, and other interactive components, which may lead to faster product development cycles and a more user-friendly and accessible design.”

FlexBoard can also enhance virtual reality gaming with controllers and gloves. The team installed a collision warning system on the controller that will alert players wearing VR headsets when they are at risk of crashing into their surroundings. Sensors and motors are added to the deformable gloves to capture gestures and influence player interactions in the game.

Each breadboard is reusable and adhesive, meaning it can withstand repeated bending in both upward and downward directions while remaining fully attached to the prototype being tested. Wessely and team evaluated the FlexBoard’s durability by bending it 1,000 times, noting that the breadboard remained fully functional without cracking afterward. This two-way flexibility helps the platform connect to items with curved designs, making FlexBoard a convenient prototyping platform for manufacturers to try different hardware to create new electronic products.

Users can cut long bread strips into smaller sections for use on smaller items, or multiple sections can be attached to prototypes of larger items. For example, multiple FlexBoards could be wrapped around a tennis racket to extend the sensor’s range when reading volley speeds.

The platform’s adaptability to different surfaces can simplify the electronic prototyping process. “When designing new interactive devices, user interfaces, or most electronic products, we often treat object form and electronic function as two separate tasks. This makes it difficult to test prototypes in their use environment early on and may lead to future integration problem,” added Junyi Zhu, a doctoral student in electrical engineering and computer science at MIT and a CSAIL affiliate. “FlexBoards solves these problems with an enhanced, reusable flexible breadboard that accelerates current interactive device prototyping processes and provides a new, valuable prototyping platform for low-power electronics design and DIY. [do-it-yourself] Community. “

In the future, FlexBoard could make fitness equipment, kitchen tools, furniture and other home items more interactive. Still, the team acknowledges that their platform needs further optimization, with multi-material printing needed to improve bendability, durability and strength. Additionally, each breadboard is designed for use with an FDM printer (an off-the-shelf 3D manufacturing machine), which limits the FlexBoard’s length and increases print time. Terminal strips also require manual assembly, which makes prototyping bendable objects challenging.

“Since many researchers have studied diverse material properties, we questioned why breadboards remain rigid,” said another author on the study, Donghyeon Ko, a former MIT visiting doctoral student from Korea Science Institute of Technology. “We want to make everyday objects ‘breadboard-able’ while developing deformable interfaces.”

Wessely, Zhu and Ko co-authored a paper about this work with CSAIL affiliate Stefanie Mueller, associate professor in MIT’s Department of Electrical Engineering, Computer Science and Mechanical Engineering, and Yoonji Kim, assistant professor in the College of Arts and Technology at Central University. The team’s research was funded by the National Research Foundation of Korea (NRF), which is funded by the Korean government, the Korean Ministry of Education, and the National Research Foundation of Korea.

FlexBoard was unveiled in April at the 2023 CHI Human Factors in Computing Systems Conference.