For larger and longer projects, assets may be moved between multiple locations each day. In this case, assets change hands and without proper records, it is impossible to track them. A lack of monitoring systems can result in hundreds of assets being lost or misplaced, resulting in unnecessary delays and costs.

To protect business assets, it’s critical to keep a close eye on all projects at all times. This is done through a process called asset monitoring.

What is asset monitoring?

To ensure that a mobile asset delivers the expected value, it is critical to closely monitor its movement. Doing so allows businesses to repair items and replenish inventory before causing delays in productivity.This process is called assets monitor Designed to ensure efficient use of business items while minimizing costs.

Asset monitoring solutions are built on cloud-based technology to provide real-time information on an item’s name, location, custodian and date of purchase. When using this process, businesses can monitor various types of assets, including machinery, buildings, furniture, and vehicles.Failure to proactively track critical assets can result in lost items, premature out-of-stocks, and ultimately disrupted workflows due to downtime or misallocation of resources.

Let’s take a look at the top 5 benefits of implementing an asset monitoring system, the steps to set it up, some industries that actively require asset monitoring systems, and their common use cases.

Why does the industry need asset monitoring?

Organizations without robust asset monitoring systems end up incurring higher unexplained costs as capital is tied up in unnecessary projects. According to research, 10-30% of a company’s fixed assets No longer owned, or classified as a ghost asset. Such assets include items that malfunction due to faulty or missing parts. These items are either written off without records or left on site for depreciation.

Asset management systems can help eliminate ghost assets by tracking items in real time. Let’s see how:

Centralized data logging

With an asset tracking and monitoring system, businesses can create labels for all of their items. These tags can be scanned into the system to enter any type of usage information. For example, if an excavator requires weekly maintenance, a schedule can be created in software that everyone in the company can access. This way, whenever maintenance is due, an alert is sent to the relevant employees. Timely remediation of assets through real-time monitoring helps prevent unpredictable delays and ensure smooth business operations.

Informed decision-making

The data collected through asset tracking systems is accurate and can be used to drive business decisions. This type of system enables you to record inventory levels for all your business assets. Using this information, administrators can set threshold levels to alert when minimum inventory levels are reached. These notifications can be used to trigger purchase orders for new inventory. All this data is recorded over time and can be analyzed to set reorder levels, thus automating the procurement process. Data trends also help predict seasonal changes over time and meet demand fluctuations.

remote access

One of the biggest benefits of setting up an asset tracking system is the ability to remotely access information and manage hosting. Administrators do not need to be physically present at an asset to monitor its usage. They can simply ask field staff to record check-ins and check-outs on their mobile app.

This data is automatically synced within the company domain on the software and can be accessed by everyone via: Remote asset monitoring. Project leaders can easily control how assets are used on site and request escrow transfers when needed.

Improve asset security

In the asset management system, you have the option to upload relevant instruction manuals and other documents that serve as guidelines for asset health monitoring.

Some common examples of this type of documentation include regulatory guidelines, maintenance checklists, and warranty details. Every time a user lands on an asset page, they can view usage and maintenance instructions, reducing the possibility of misuse and accidents on the job site.

Loss and theft protection

Real-time barcode tracking enables organizations to control the movement of assets across multiple locations at any time. In addition to this, asset management solutions also record custodian data every time an item is checked out and transferred to another location.

Instant access to custody and item location helps maintain a usage trail to track misplacement when it occurs. In this way, GPS tracking reduces the likelihood of asset loss and theft, thereby saving costs and preventing productivity delays.

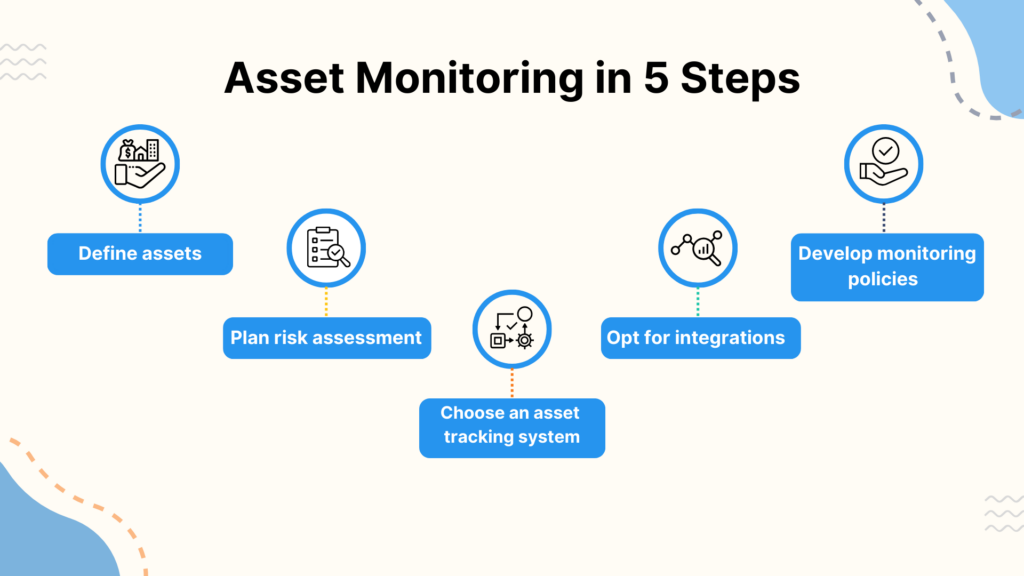

How to set up an asset monitoring system?

In order to implement a successful asset monitoring solution, businesses need to follow a few simple steps:

1. Define your assets

Start by listing the types and amounts of assets you own. These can be physical assets such as furniture, vehicles and machinery. Group them together based on purpose, location, or project. This will allow you to classify assets and define guidelines for their maintenance and tracking schedules.

2. Conduct a risk assessment

Document threats and vulnerabilities associated with each asset. Assets that are used heavily on a daily basis require frequent maintenance and service.

For example, hospital ambulances are used to transport patients to and from the hospital in emergencies. Such vehicles require scheduled routine maintenance and regular replenishment of emergency supplies. In addition to this, consider any legal or regulatory requirements that may affect asset tracking.

3. Choose an asset monitoring solution

There are a variety of tools on the market, and it’s best to make a decision based on your asset requirements and budget. Cloud-based technology provides real-time data by tracking items at all times. Such solutions leverage barcode, QR code and GPS technology to access critical information such as ownership, location and condition.

With automated tracking, it’s easier to retain accurate information without missing important details, improving performance and asset productivity.

4. Select integration

Effective monitoring solutions are able to integrate with other software to provide total control of operations. For seamless health monitoring, a suitable integration is with a help desk software that can track and expedite all repair orders created for streamlined maintenance. In addition to this, integration enables centralization of data across multiple platforms, which helps in making informed decisions on key aspects of maintenance and procurement.

5. Develop a monitoring policy

Clearly define health monitoring guidelines that should be followed by all assets across the organization. These can be in the form of Standard Operating Procedures (SOPs) so that they can be easily put into practice. It is common for heavy equipment and machinery to have certain maintenance requirements that can only be met by the manufacturer.

Train employees on equipment maintenance considerations to increase uptime.

Critical Asset Monitoring Use Cases

Asset condition monitoring is an essential process across industries, helping them overcome unplanned downtime, predict maintenance needs, and operate smoothly. This can be achieved through barcode tracking, which provides real-time information on how and where assets are used. Let’s look at some use cases where asset condition monitoring is particularly useful:

Transportation and Logistics: Track equipment, merchandise and vehicles through technologies such as barcodes, QR codes or RFID.

manufacturing: Condition monitoring minimizes downtime by predicting failures before they occur. Asset health monitoring can also be used to track product quality to maintain standards throughout the process.

health care: GPS tags are used to track medical equipment such as MRI machines and ventilators to avoid last-minute malfunctions.

Fleet management: Maintain records of vehicle purchase, use and disposal to allow for proper management of all fleet assets. Meet compliance regulations to improve performance and reduce costs.

How can an asset tracking system help?

Asset management software provides powerful facilities to track assets in real-time using various technologies such as barcode scanners, GPS, and RFID. Asset tags help collect accurate information, allowing businesses to monitor the condition of their items throughout their lifecycle.

Businesses can implement quality control measures by tracking compliance regulations and their assets. Doing so ensures product standardization across departments while reducing hefty fines. In addition to this, the asset management system also issues alerts on critical events such as maintenance, procurement and disposal to ensure seamless operational productivity at all times.

frequently asked questions

What is asset monitoring?

Asset monitoring is the process of tracking items owned by a business. All corporate assets are tagged with barcodes, QR codes or RFID and then simply scanned to populate information about usage, procurement, maintenance and location.

Why is asset monitoring important?

Asset monitoring provides real-time and accurate information about the location, status and condition of items. Without this critical data, businesses end up losing valuable assets, suffering unexpected outages, and even incurring hefty fines due to breaches. To avoid inefficiencies and unnecessary costs, it is important to implement asset monitoring.

How to set up asset monitoring?

Set up asset monitoring in three easy steps. Start by listing your physical assets and determining the nature of their use. Next calculate the risks involved and the actions required to avoid them. Finally, choose an asset management system that fits your workflow to track and maintain your assets.