Imagine that instead of wearing a coat every season, you have a jacket that dynamically changes shape so that it becomes more insulated, keeping you warm when the temperatures drop.

Programmable actuation fibers developed by an interdisciplinary team of MIT researchers could one day make this vision a reality. The fiber, called FibeRobo, shrinks as temperature increases and then reverses itself when the temperature decreases, without the need for any embedded sensors or other hard components.

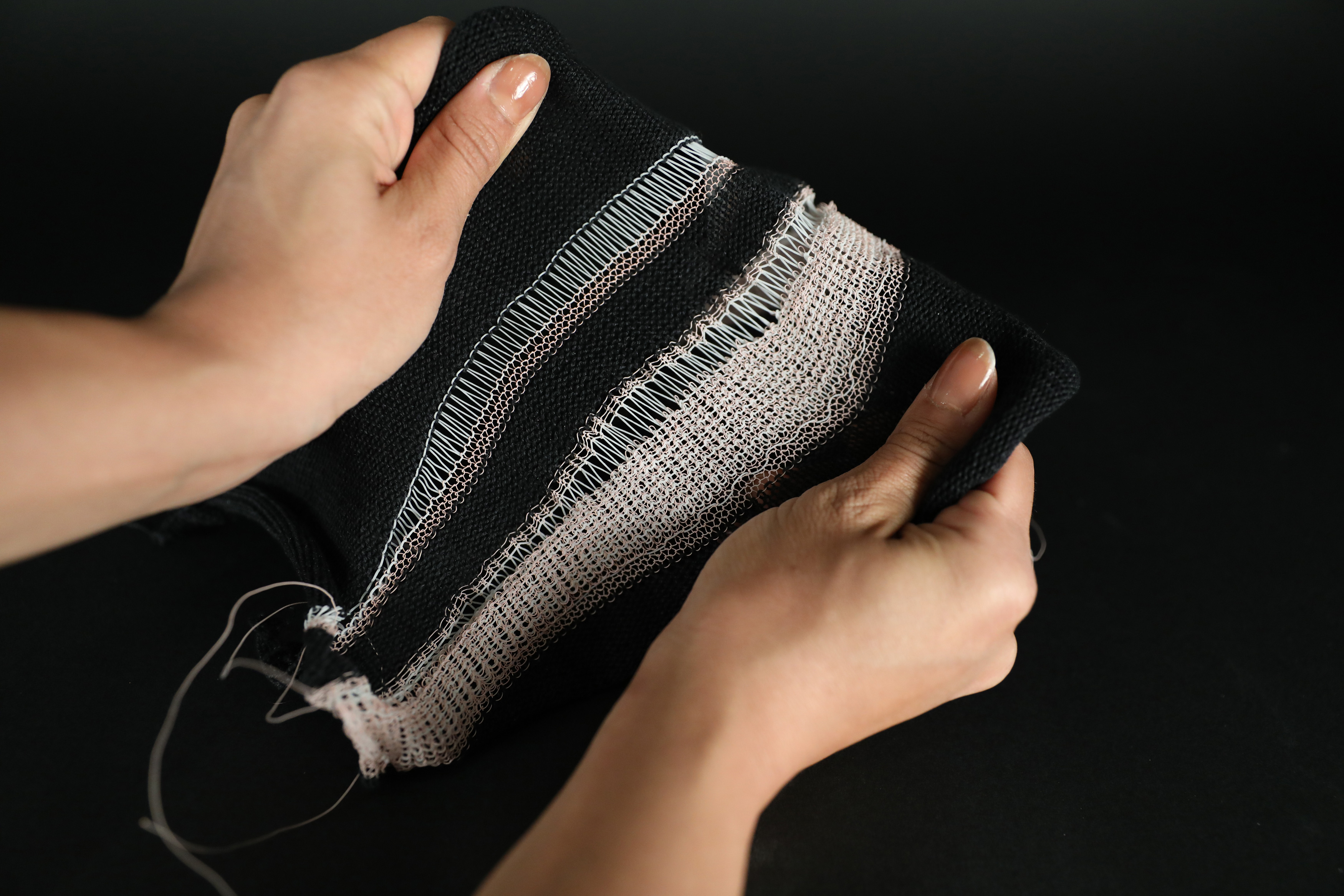

This low-cost fiber is fully compatible with textile manufacturing technologies, including looms, embroidery and industrial knitting machines, and can be produced continuously on a kilometer basis. This allows designers to easily incorporate actuation and sensing functionality into a variety of fabrics to suit a variety of applications.

The fibers can also be combined with conductive threads, which act as heating elements when electricity is passed through them. In this way, the fibers are powered using electricity, giving the user digital control over the shape of the textile. For example, fabric can change shape based on any digital information, such as readings from a heart rate sensor.

“We use textiles for everything. We build airplanes with fiber-reinforced composites, cover the International Space Station with radiation-shielding fabrics, and we use them for personal expression and functional clothing. So much of our environment is adaptable and responsive , but the things that need to be adaptable and responsive the most—textiles—are completely inert,” said Jack Forman, a graduate student in the Tangible Media Group at the MIT Media Lab. A second affiliate of the Center for Bits and Atoms and lead author of the paper on driving fiber optics.

He was joined on the paper by 11 other researchers from MIT and Northeastern, including his advisor Professor Neil Gershenfeld, director of the Center for Bits and Atoms, and the Jerome B. Wiesner Professor and Director of Media Arts and Sciences Hiroshi Ishii. Tangible Media Group. The research will be presented at the ACM Symposium on User Interface Software and Technology.

deformable material

MIT researchers wanted a fiber that could be driven silently and significantly change its shape, while being compatible with common textile manufacturing procedures. To achieve this, they used a material called liquid crystal elastomer (LCE).

Liquid crystals are a series of molecules that can flow like a liquid, but when they settle, they pile up into periodic crystal arrangements. The researchers integrated these crystal structures into an elastomer network that is as stretchy as a rubber band.

As the LCE material heats up, the crystalline molecules lose alignment and pull the elastomer network together, causing the fibers to shrink. Forman explains that when the heat is removed, the molecules return to their original arrangement and the material returns to its original length.

By carefully mixing chemicals to synthesize LCE, researchers can control the fiber’s final properties, such as its thickness or actuation temperature.

They perfected a preparation technique that produces LCE fibers that can be driven at skin-safe temperatures, making them suitable for use in wearable fabrics.

“There were a lot of knobs we could turn. It was a lot of work to figure out the process from scratch, but in the end it gave us a lot of freedom in the fibers we got,” he adds.

However, the researchers found that making fibers from LCE resin is a finicky process. Existing techniques often produce fusions that cannot be unraveled.

Researchers are also exploring other ways to make functional fibers, such as integrating hundreds of tiny digital chips into polymers, utilizing activated fluidic systems, or using piezoelectric materials that can convert sound vibrations into electrical signals.

Optical fiber manufacturing

Forman built a machine using 3D printed and laser-cut parts and basic electronics to overcome manufacturing challenges.He originally built the machine as part of the graduate course MAS.865 (Rapid Prototyping: How to Make Things That Can Be Made) [almost] anything).

First, thick and viscous LCE resin is heated and then slowly squeezed through a nozzle like a glue gun. As the resin comes out, it is carefully cured using UV light that shines on both sides of the slowly extruded fiber.

If the light is too dark, the material will separate and drip out of the machine, but if the light is too bright, clumps will form, resulting in bumpy fibers.

The fibers are then dipped in oil, giving them a smooth coating and cured again, this time with the UV lamp turned to maximum intensity, resulting in strong and smooth fibers. Finally, it is collected into a top spool and dipped in powder so that it can easily slide into textile manufacturing machines.

The process takes about a day from chemical synthesis to finished spool and produces about one kilometer of ready-to-use fiber.

“Ultimately, you don’t want diva fiber. You want a fiber that, when you use it, belongs in a collection of materials—you can use it like any other fiber material, but it has a lot of exciting new capabilities ,” Foreman said.

Making the fiber required a lot of trial and error, as well as the collaboration of researchers with expertise in multiple disciplines including chemistry, mechanical engineering, electronics and design.

The resulting fiber, called FibeRobo, can shrink by up to 40% without bending, operates at skin-safe temperatures (skin-safe versions of the fiber shrink by up to about 25%), and is produced in a low-cost setup20 At 5 cents per meter, it is about 60 times cheaper than commercially available textured fibers.

The fiber can be used on industrial sewing and knitting machines, as well as non-industrial processes such as handlooms or manual crocheting, without any process modifications.

MIT researchers have used FibeRobo to demonstrate a variety of applications, including an adaptive sports bra made from embroidery that tightens when the user starts exercising.

They also used an industrial knitting machine to create a compression jacket for Foreman’s dog, named Professor. The jacket drives and “hugs” the dog based on Bluetooth signals from Foreman’s smartphone. Compression jackets are often used to relieve separation anxiety that dogs feel when their owners are away.

In the future, the researchers hope to tweak the fiber’s chemical composition to make it recyclable or biodegradable. They also hope to simplify the polymer synthesis process so that users without wet lab expertise can make their own.

Forman is excited to see other research groups build on these early results and identify applications for FibeRobo. In the long term, he hopes FibeRobo will become something manufacturers can buy at craft stores, like balls of yarn, and use to easily produce shape-shifting fabrics.

“When LCE fibers are incorporated into functional textiles, they come to life. It was particularly interesting to observe how the authors explored creative textile designs using a variety of weaving and knitting patterns,” said Cooper-Siegel, Carnegie Mellon University said Lining Yao, an associate professor of computer interaction who was not involved in the work. .

This research was supported in part by the William Asbjornsen Albert Memorial Scholarship, the Dr. Martin Luther King Jr. Visiting Professorship Program, Toppan Printing Company, Honda Research Institute, China Scholarship Council, and Shima Seiki Corporation . The team includes Ozgun Kilic Afsar, Sarah Nicita, Rosalie (Hsin-Ju) Lin, Liu Yang, Akshay Kothakonda, Zachary Gordon, and Cedric Honnet of MIT; and Megan Huffman and Kristin Hofmann of Northeastern University. Dorsey.